Ever wonder how AMG made all the odd shaped structures? The precision and perfection that is needed to eliminate the slightest error? It is obvious that no human can crank out a thousand pieces of panels in a single day.

Here is where the magic comes from:

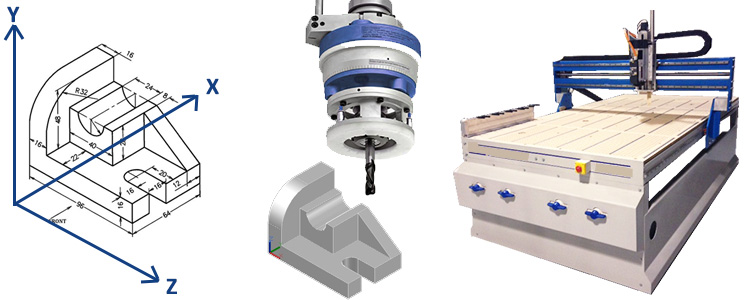

The CNC router is used in the production of many different items, such as door carvings, interior and exterior decorations, wood panels, sign boards, wooden frames, moldings, musical instruments, furniture, and so on. In addition, the CNC router helps in the thermoforming of plastics by automating the trimming process. It can help ensure part repeatability and sufficient factory output. It reduces waste, frequency of errors, and the time the finished product takes to get to market. Automation and precision are the key benefits of CNC router tables. The CNC works on the Cartesian coordinate system (X, Y, Z) for 3D motion control. CAM software makes the CAD drawing/design into a code called g-code. This code the CNC machine can understand. Parts of a project can be designed in the computer with a CAD/CAM program, and then cut automatically using a router or other cutters to produce a finished part.

Now, knowing its ability and the resources we have, the rest is merely just your imagination. The possibility is endless.